Designing-a-replacement-part-for-my-truck.md (4237B)

- ---

- date: 2020-03-25

- title: Designing and 3D printing a new part for my truck

- layout: post

- ---

- I drove a car daily for many years while I was living in Colorado, California,

- and New Jersey, but since I moved to Philadelphia I have not needed a car. The

- public transit here is not great, but it's good enough to get where I need to be

- and it's a lot easier than worrying about parking a car. However, in the past

- couple of years, I have been moving more and more large server parts back and

- forth to the datacenter for SourceHut. I've also developed an interest in

- astronomy, which benefits from being able to carry large equipment to remote

- places. These reasons, among others, put me into the market for a vehicle once

- again.

- I think of a vehicle strictly as a functional tool. Some creature comforts are

- nice, but I consider them optional. Instead, I prioritize utility. A truck makes

- a lot of sense — lots of room to carry things in. And, given my expected

- driving schedule of "not often", I wasn't looking to spend a lot of money or

- get a loan. There are other concerns: modern cars are very complicated machines,

- and many have lots of proprietary computerized components which make end-user

- maintenance very difficult. Sometimes manufacturers even use cryptography and

- legal threats to bring cars into their dealerships, bullying out third-party

- repairs.

- To avoid these, I got an older truck: a 1984 Dodge D250. It's a much simpler

- machine than most modern cars, and learning how to repair and maintain it is

- something I can do in my spare time.

- It's an old truck, and the previous owners were not negligent, but also didn't

- invest a lot of time or money in the vehicle's upkeep. The first problem I hit

- was the turn signal lever snapping and becoming slack, which I fixed by pulling

- open the steering column, re-aligning the lever, and tightening an internal

- screw. The more interesting problem, however, was this:

-

- This plastic part holds an arm in place, which is engaged by a lever in the

- center of the window which folds closed over the truck bay. It's used to hold

- the window in place and provides a weak locking mechanism. When the arm is

- allowed to move freely, it can clang around while I'm driving, and can make

- opening the truck bay a frustrating procedure. I have been looking for a reason

- to learn how to use [solvespace](http://solvespace.com/index.pl), and this

- seemed like a great start.

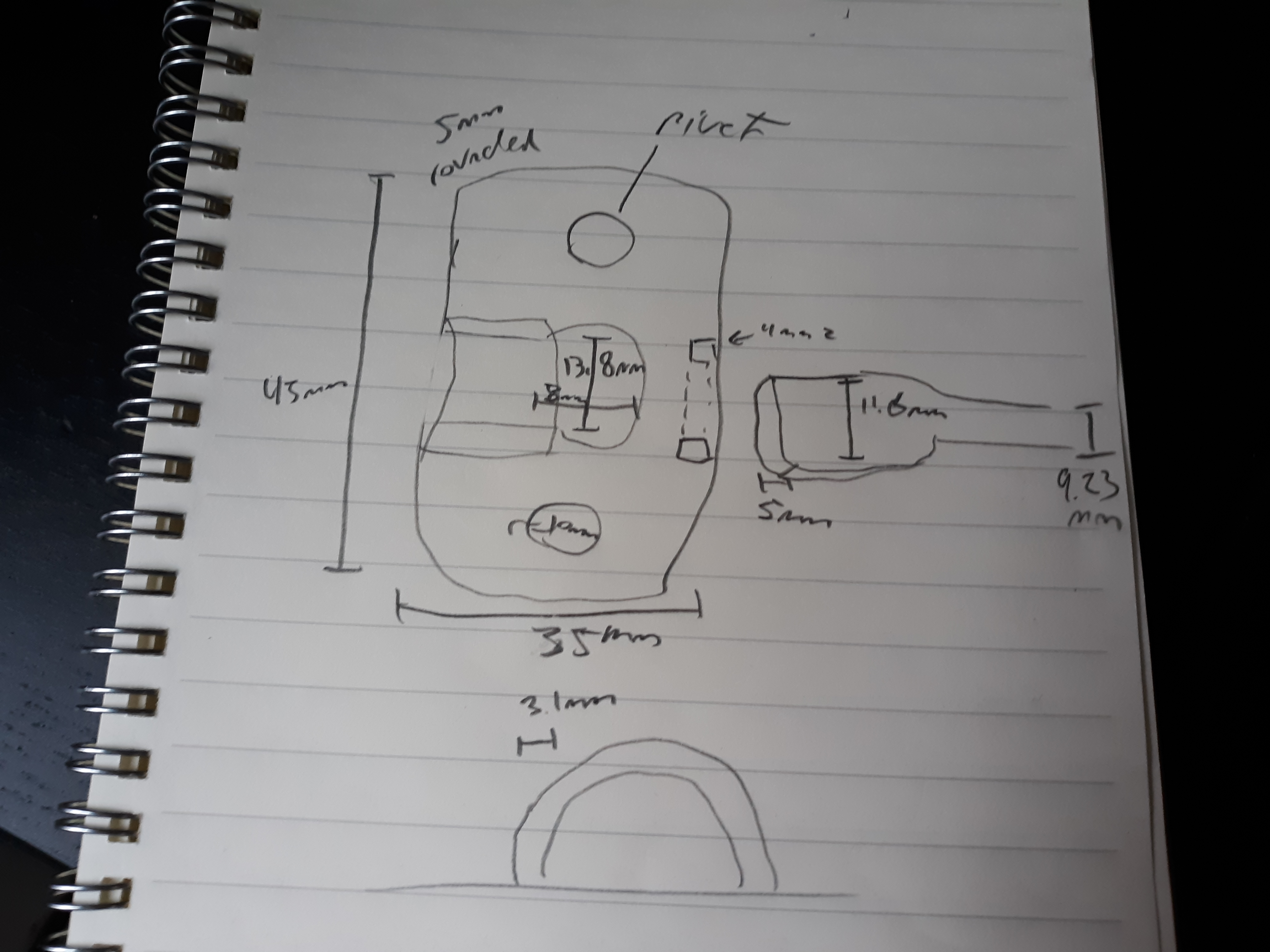

- I ordered a caliper[^1] and measured the dimensions of the broken part, and took

- pictures of it from several angles for later reference. I took some notes:

- [^1]: Oh man, I've always wanted a caliper, and now I have an excuse!

-

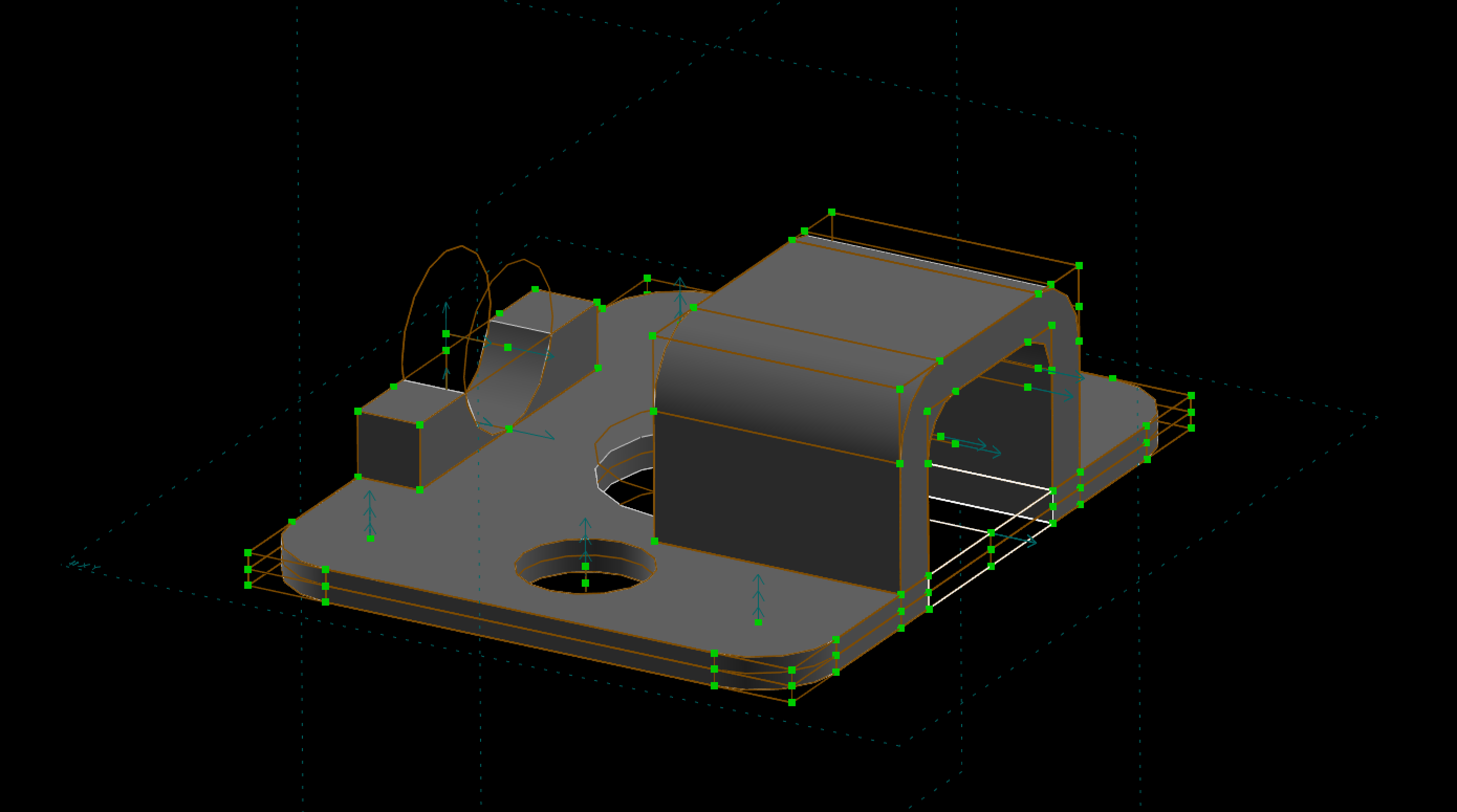

- Then, I used solvespace to design the following part:

-

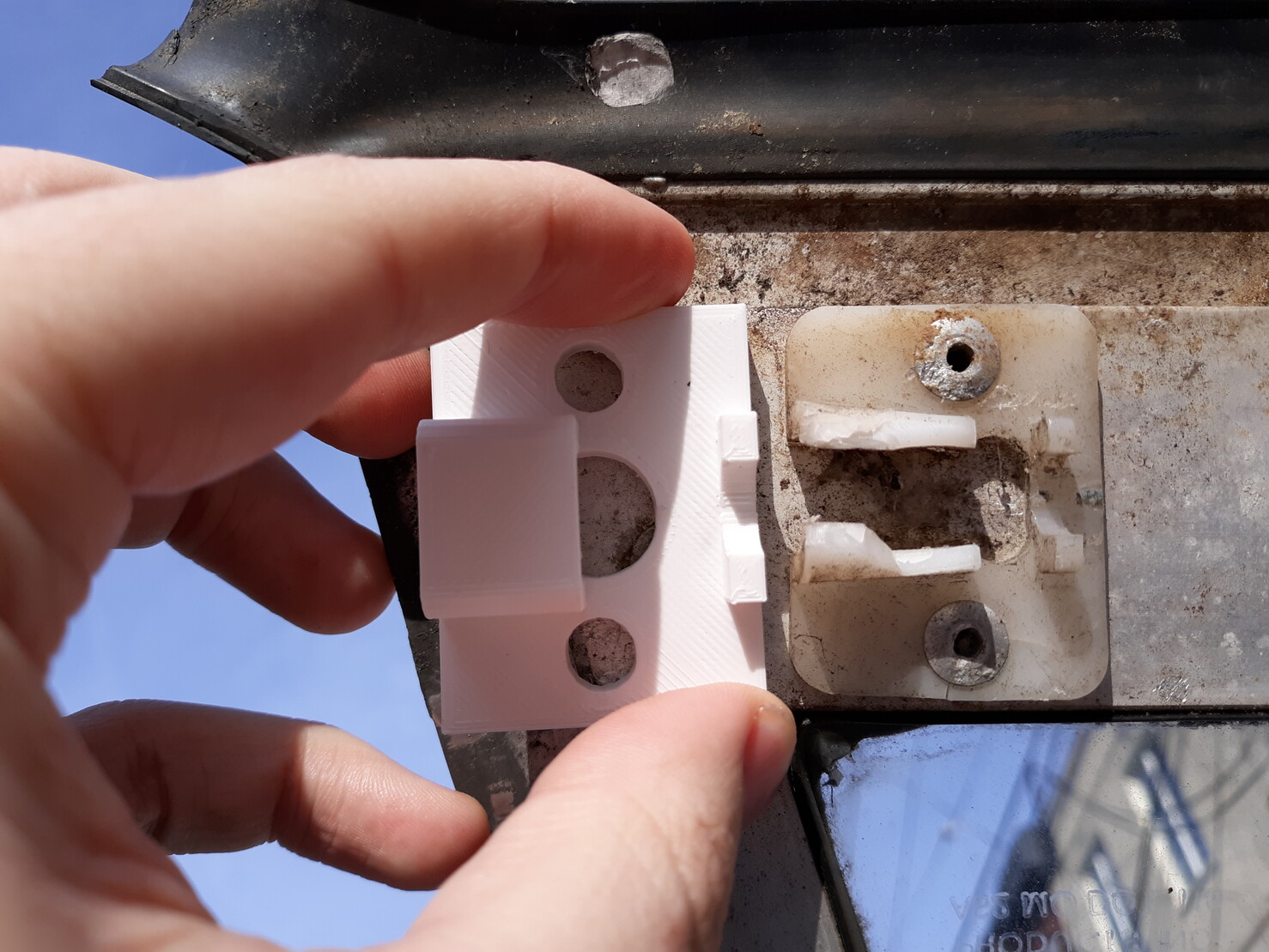

- This was the third iteration — I printed one version, brought it out to

- the truck to compare with the broken part, made refinements to the design, then

- rinse and repeat. Here's an earlier revision being compared with the broken

- piece:

-

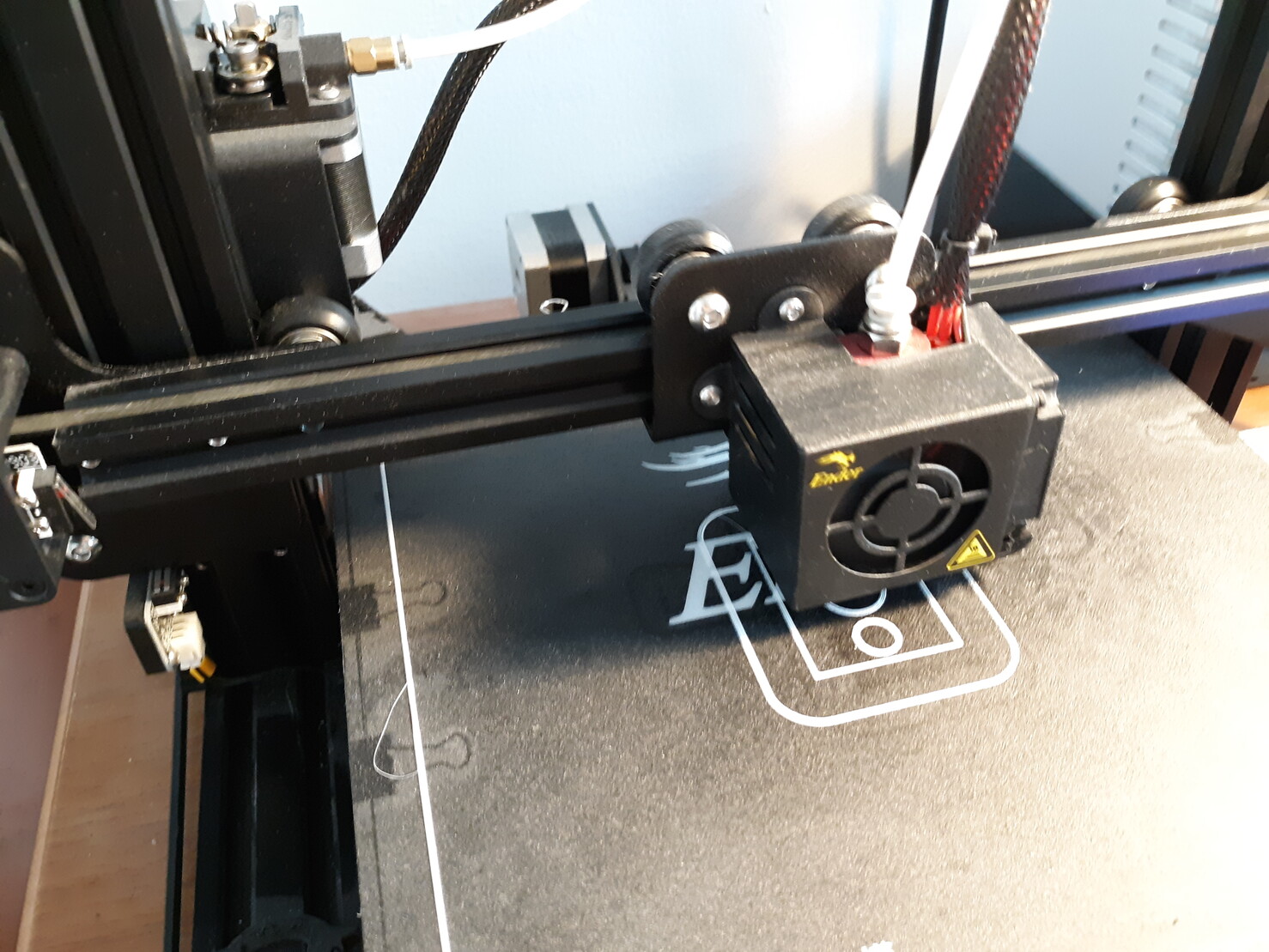

- Finally, I arrived at a design I liked and sent it to the printer.

-

- I took some pliers to the remaining plastic bits from the broken part, and sawed

- off the rivets. I attached the replacement with superglue and ta-da!

-

- If the glue fails, I'll drill out what's left of the rivets and secure it with

- screws. This may require another revision of the design, which will also give me

- a chance to address some minor shortcomings. I don't expect to need this,

- though, because this is not part under especially high stress.

- You can get the CAD files and an STL from my [repository

- here](https://git.sr.ht/~sircmpwn/open-dodge-d250), which I intend to keep

- updating as I learn more about this truck and encounter more fun problems to

- solve.